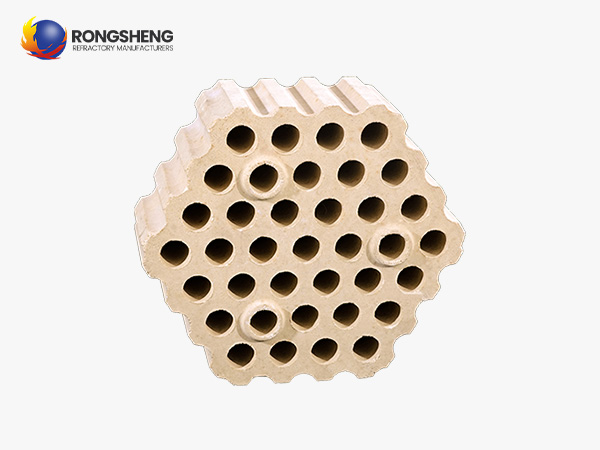

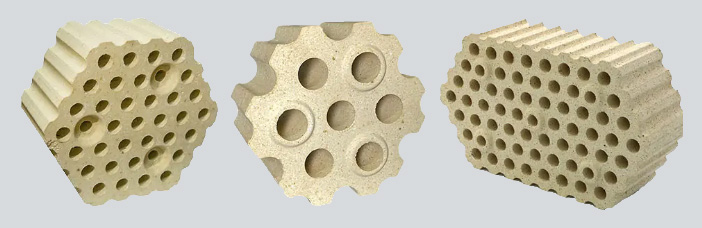

Product Introduction

Checker brick is a heat transfer medium used in hot blast stoves, glass kilns, etc. And high-alumina checker brick is a heat-carrying and heat-storing body with strong heat exchange capacity, large heat storage area, smooth ventilation, and small resistance. It has the advantages of good volume stability, excellent high-temperature creep performance, high density and low porosity.

Choose the type what you need, or provide the size you need.

Technical Data

| Item | Index | |||

| GZ | DRN120 | DRL127 | DRL145 | |

| Al2O3 % | ≤1.0 | ≥42 | ≥50 | ≥65 |

| SiO2 % | ≥95 | / | / | / |

| Fe2O3 % | ≤1.2 | ≤1.8 | / | / |

| Apparent Porosity % | ≤24 | ≤22 | ≤25 | ≤23 |

| Bulk Density g/cm3 | ≤2.34(True density) | 2.1~2.3 | 2.3~2.5 | 2.5~2.7 |

| Normal Temperature Compressive Strength MPa | ≥30 | ≥25 | ≥40 | ≥50 |

| 0.2MPaCreep Rate % 0~50h | ≤0.8 | ≤0.8 | ≤0.8 | ≤0.8 |

| 1500℃ | 1200℃ | 1270℃ | 1450℃ | |

| Thermal Expansion Rate % 1000℃ | ≤1.26 | / | / | / |

| Heating Permanent Line Change % | / | 1350℃×2h | 1450℃×2h | 1500℃×2h |

| -0.4~0.1 | -0.3~+0.2 | ±0.2 | ||

Application

1. Steel furnaces

2. Iron making furnaces

3. Glass kiln

4. Ceramic tunnel kiln

5. Cement kiln