Brief Introduction

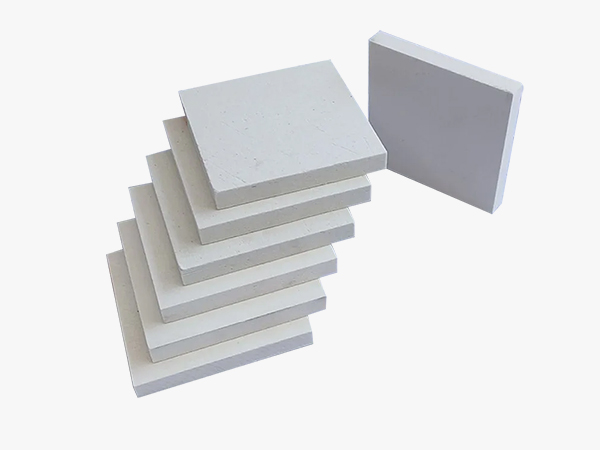

Ceramic fiber board in Rongsheng company can be divided in to 5 kinds types: Common ceramic fiber board 1100(2012℉), Standard ceramic fiber board 1260(2300℉), High pure Ceramic fiber board 1260(2300℉), High Alumina ceramic fiber board 1360(2480℉), High zircon ceramic fiber board 1430(2606℉), In addition, we also can customized the ceramic fiber board, making the temperature up to 1600℃/3000℉.

Technical Data

| Type | common | standard | high pure | high aluminum | zircon | |

| classfication Temperature(℃) | 1100(2012℉) | 1260(2300℉) | 1260(2300℉) | 1360(2480℉) | 1430(2606℉) | |

| Working Temperature(℃) | 950℃(1832℉) | 10501150(1922℉) | 1100(2012℉) | 1200(2192℉) | 1350(2462℉) | |

| color | white | pure white | pure white | pure white | pure white | |

| Shrinkage on heating (%)(Temperature 24 hours, density as 128kg/m3) |

-4 (1000°C) |

-3 (1000°C) |

-3 (1100°C) |

-3 (1200°C) |

-3 (1350°C) |

|

| Thermal conductivity of various temperatures (w/m.k) (density 128kg/m3) |

0.085(400°C) 0.132(800°C) 0.18(1000°C) |

0.085(400°C) 0.132(800°C) 0.18(1000°C) |

0.08(400°C) 0.13(800°C) 0.1(1000°C) |

0.085(400°C) 0.132(800°C) 0.18(1000°C) |

0.085(400°C) 0.132(800°C) 0.18(1000°C) |

|

| Compressive strength (Mpa) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |

| Chemical composition (%) | AL2O3 | 44 | 46 | 47-49 | 52-55 | 39-40 |

| AL2O3+SIO2 | 96 | 97 | 99 | 99 | – | |

| AL2O3+SIO2+ZrO2 | – | – | – | – | 99 | |

| ZrO2 | – | – | – | – | 15-17 | |

| Fe2O3 | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 | |

| Na2O+K2O | <0.5 | <0.5 | 0.2 | 0.2 | 0.2 | |

| Dimensions (mm) | Common Specifications(Length*Width& Thickness): 600*300*10-50;600*400*10-50; 900*600*10-50;1200*800*10-50; 1200*1000*10-50;1000*600*10-50 Other dimension can be available. |

|||||

Application

▸Back lining thermal insulation material for tundish and launder cover, casting copper.

▸Expansion gap, back lining thermal insulation, heat resisting sheet and casting mould heat insulation.

▸Insulation for Iron and steel industry, Nonferrous industry, Ceramic industry, Glass industry, Petrochemical and Architectural industry.

▸Hot side lining body of light trucks and kiln furnace, thermal and fire insulation materials for each temperature area of kiln.

▸Back lining thermal insulation of furnace hearth, nozzle block and Lining for combustor of industry and domestic boiler.

▸Hot side refractory for lining of high heating furnace and Thermal insulation for cement rotary kiln & Kiln building.