Brief Introduction

We produce and sell graphite electrodes and nipples to them. According to its high quality and low quality, it can be divided into ordinary power graphite electrode, high power graphite electrode and ultra high power graphite electrode. Any interests for our graphite electrode, pls email us for more information :info@refractorymanufacture.com

Classification Of Graphite Electrode

▸General Power Graphite Electrodes (RP)

▸Impregnation Power Graphite Electrodes (IP)

▸High Power Graphite Electrodes (HP)

▸Special Power Graphite Electrodes (SHP)

▸Ultra High Power Graphite Electrodes (UHP)

▸High Density Graphite Electrodes (HD)

Technical Data Of Graphite Electrode RP,HP,UHP

| Name | Unit | Nominal Diameter | ||||||

| UHP Ultra-High-Power | HP Superstrong | RP Conventional Power | ||||||

| ≤Φ400 | ≥Φ450 | ≤Φ400 | ≥Φ450 | ≤Φ300 | ≥Φ350 | |||

| Resistivity | Electrode | ΜΩ · m | ≤5.5 | ≤6.5 | ≤8.5 | |||

| Nipple | ≤4.5 | ≤5.5 | ≤6.5 | |||||

| Flexural Strength | Electrode | MPa | ≥11.0 | ≥10.5 | ≥9.8 | ≥8.5 | ≥7.0 | |

| Nipple | ≥20.0 | ≥16.0 | ≥15.0 | |||||

| Elastic Modulus | Electrode | GPa | ≤14.0 | ≤12.0 | ≤9.3 | |||

| Nipple | ≤18.0 | ≤16.0 | ≤14.0 | |||||

| Density | Electrode | g / cm3 | ≥1.66 | ≥1.67 | ≥1.62 | 1.6 | ≥1.53 | ≥1.52 |

| Nipple | ≥1.75 | ≥1.73 | ≥1.69 | |||||

| Coefficient Of Thermal Expansion | Electrode | 10-6 / ℃ | ≤1.5 | ≤2.4 | ≤2.9 | |||

| Nipple | ≤1.4 | ≤2.2 | ≤2.8 | |||||

| ASH | % | ≤0.3 | ≤0.3 | ≤0.5 | ||||

| Note: 1.Koeffitsient ash content and thermal expansion as the reference index, the coefficient of thermal expansion (100 ℃ ~ 600 ℃), Custom manufacturing. | ||||||||

Technical Data Of High Density Graphite Electrode (HD)

Technical Data Of Quasi-Superhigh-Gauge Graphite Electrode

| Name | Unit | Nominal Diameter (mm) | ||

| 300, 350, 400 | 450, 500 | |||

| Resistivity (not more than) | Electrode | ΜΩ · m | 6.2 | 6.5 |

| Nipple | 5.5 | 5.5 | ||

| Flexural Strength(not less than) | Electrode | MPa | 10.5 | 10 |

| Nipple | 16 | 16 | ||

| Elastic Modulus(no more) | Electrode | GPa | 14 | 14 |

| Nipple | 18 | 18 | ||

| Density(not less than) | Electrode | g / cm3 | 1.65 | 1.64 |

| Nipple | 1.72 | 1.7 | ||

| Coefficient Of Thermal Expansion (no more) | Electrode | 10-6 / ℃ | 1.5 | 1.5 |

| Nipple | 1.4 | 1.4 | ||

| Ash Content (not more than) | % | 0.3 | 0.3 | |

| Note: 1. Zonality as a reference index. | ||||

Length & Diameter & Permissible Deviation

| Nominal Diameter | Actual Diameter | Length (mm) | Tolerance | ||||

| MM | Inch | Poppy | Mines | The Minimum Size Of The Black Part | Length | Short Length | |

| 75 | 3 | 78 | 73 | 72 | 1400/1600 | ± 100 | -275 |

| 100 | 4 | 103 | 98 | 97 | 1400/1600 | ||

| 130 | 5 | 132 | 127 | 126 | 1400 | ||

| 150 | 6 | 154 | 149 | 146 | 1400/1600/1800 | ||

| 175 | 7 | 180 | 174 | 172 | 1400/1600 | ||

| 200 | 8 | 205 | 200 | 197 | 1600/1800 | ||

| 225 | 9 | 230 | 225 | 222 | 1600/1800 | ||

| 250 | 10 | 255 | 251 | 248 | 1600/1800 | ||

| 300 | 12 | 307 | 302 | 299 | 1600/1800/2000 | ||

| 350 | 14 | 357 | 352 | 349 | 1600/1800/2000 | ||

| 400 | 16 | 409 | 403 | 400 | 1600/1800/2000/22000 | ||

| 450 | 18 | 460 | 454 | 451 | 1600/1800/2000/22000 | ||

| 500 | 20 | 511 | 505 | 502 | 1600/1800/2000/22000 | ||

| 550 | 22 | 562 | 556 | 553 | 1800/2000/2200/2400 | ||

| 600 | 24 | 613 | 607 | 604 | 2000/2200/2400/2700 | ||

| 650 | 26 | 663 | 659 | 656 | 2000/2200/2400/2700 | ||

| 700 | 28 | 714 | 710 | 707 | 2000/2200/2400/2700 | ||

➥Diameter Available

▸For RP grade, the Diameter is usually 100 -1060MM.

▸For RPI grade, the Diameter is usually 200 -650MM.

▸For HP grade, the Diameter is usually 300-650MM.

▸For SHP grade, the Diameter is usually 400-650MM.

▸For UHP grade, the Diameter is usually 400-650MM.

Applications

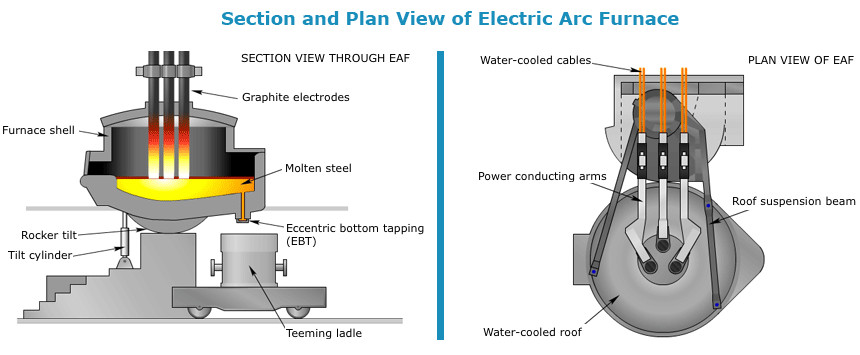

▸Mainly used for electric arc furnace (EAF) steel production

▸For ore-thermal furnace; for the resistance furnace

▸For the production of profiled graphite products

▸For the production of shaped graphite products

▸Also can used For a resistor furnace

▸For the production of graphite shaped products